Chapter 1. What is the capacity of the fuel tanker?

Chapter 3. What materials and processes are used in semi tanker trailer?

Chapter 4. How to maintain and maintain fuel tanker trailer?

A fuel tanker is a special trailer used to transport liquid petroleum products and other liquid products. It usually consists of an oil tank and a chassis. The common capacity of fuel tanker for sale is about 30,000 liters, which can reach or even exceed 55,000 liters. It is suitable for the transportation needs of large-scale liquid petroleum products.

Common specifications:

Number of axles: fuel tankers for sale in Rwanda generally have 3 or 4 axles, and sometimes are designed with more axles to increase load-bearing capacity and reduce tire wear.

Chassis length: usually 12 to 15 meters, may vary depending on capacity and usage requirements.

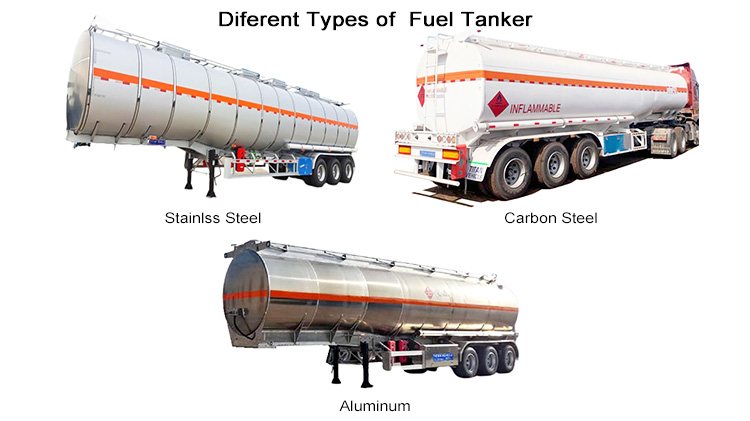

Tank structure: The tank of fuel tanker from TITAN generally adopts an oval structure, and the material is mostly carbon steel, stainless steel or aluminum alloy.

Tank compartments: The fuel tanker price can have multiple compartments to transport different types or qualities of liquid petroleum products at the same time.

Loading and unloading methods: Common loading and unloading methods include top loading and unloading, bottom loading and unloading and rear loading and unloading, which may differ according to specific needs.

Safety equipment: The fuel tanker will be equipped with safety equipment, such as overflow prevention devices, pressure relief valves, safety valves, etc., to ensure safety during transportation.

In order to ensure the safety of diesel tanker, TITAN will take the following safety measures:

Tank structure: The tank structure of diesel tanker must be strong and durable, not prone to deformation and damage, and is usually made of high-strength materials, such as carbon steel, stainless steel or aluminum alloy. At the same time, anti-corrosion treatment should be carried out inside the tank to prevent liquid corrosion and contamination.

Safety valve and pressure relief valve: diesel tanker is equipped with safety valve and pressure relief valve and other devices. These devices can automatically open when the pressure is abnormal to reduce the internal pressure of the tank and prevent explosion.

Liquid level monitoring system: Diesel tanker is equipped with a liquid level monitoring system, which can monitor the liquid level in the tank in real time, predict the movement of the liquid in the tank, and avoid fluctuations and instability caused by excess cargo.

Electronic anti-static equipment: Since diesel tankers transport flammable and explosive petroleum products, they must be equipped with electronic anti-static equipment to eliminate the danger of static electricity.

Anti-spill device: Diesel tankers must also be equipped with anti-spill devices to avoid liquid leakage and environmental pollution during transportation.

In order to ensure driver and traffic safety, the following measures need to be taken:

Basic skills training: Drivers who drive diesel tankers should receive professional training and master basic driving skills and operating knowledge.

Safety regulations: Drivers should follow relevant safety regulations and operating procedures, pay attention to safe driving during driving, and avoid accidents.

Driver's rest: In order to ensure the driver's driving safety, it is necessary to arrange reasonable driver rest time to avoid fatigue driving.

In short, the safety of diesel tankers is very important, and a series of standards and regulations need to be followed during the design, manufacturing and use processes to ensure driver and driving safety.

The tank material and craftsmanship of semi tanker trailer are important factors affecting its quality and service life. The following are some common tank materials and processes for oil tank semi-trailers:

Material: The tank material of semi tanker trailer for sale can be steel, aluminum, stainless steel, etc. Steel tanks usually use Q235 carbon structural steel or Q345 low-alloy high-strength steel, which has the advantages of durability and low cost, but is heavy and susceptible to corrosion. Aluminum tanks are made of high-strength aluminum alloy, which has the advantages of being lightweight and corrosion-resistant, but the cost is higher. Stainless steel tanks are made of stainless steel, which has the advantages of corrosion resistance and easy cleaning, but the cost is also higher.

Process: The tank manufacturing process of semi tanker trailer for sale in Rwanda generally includes welding, stamping, forming, etc. Welding is the main process for manufacturing semi tanker trailer from TITAN tanks. Commonly used welding methods include manual arc welding, gas shielded welding, submerged arc welding, etc. The quality of welding directly affects the service life and safety of semi tanker trailer. Stamping and forming are auxiliary processes for manufacturing oil tank semi-trailer tanks, which can make the shape of the tank more precise and beautiful.

In short, the tank material and process of semi tanker trailer price are important factors in manufacturing oil tank semi-trailers. Different materials and processes can affect the quality, service life and safety of semi tanker trailer.

Operational matters:

Before operation, check the overall condition of the fuel tanker trailer, including tires, braking system, lights, etc., to ensure that it is operating normally.

Before loading, check whether the oil tank and pipeline are intact to eliminate the risk of leakage and damage.

When loading, it must be loaded according to the specified loading capacity and must not be overloaded to ensure safe transportation.

During driving, maintain a stable driving speed, avoid sudden acceleration and braking, turn smoothly, and pay attention to road signs and traffic signals.

Maintenance matters:

Regularly inspect the exterior and interior of the fuel tanker trailer for sale to prevent problems such as rust, corrosion, and oil leakage. If damage or abnormality is found, it should be repaired or replaced in time.

When cleaning tanks and pipes, appropriate protective measures must be taken to avoid personnel exposure to harmful substances.

Regularly check and replace lubricating oil, brake oil, coolant, etc. to ensure the normal operation of each system.

Keep the fuel tanker trailer for sale in Rwanda in good clean condition to prevent the accumulation of debris and oil stains, which may cause safety hazards.

Pay attention to the looseness of fastening bolts and connectors, and repair and tighten them in time.

Safety Precautions:

It is strictly prohibited to smoke or use open flames next to the fuel tanker trailer from TITAN, and be careful to prevent static electricity accumulation and contact with fire sources.

Obey traffic laws and avoid illegal behaviors such as speeding, fatigue driving and drunk driving.

Participate in relevant training and assessments regularly to improve driver skills and safety awareness.

In short, the operation and maintenance of fuel tanker trailer price need to be carried out in strict accordance with the prescribed requirements to ensure that it can transport petroleum products safely and reliably. At the same time, drivers must also possess professional knowledge and skills, enhance safety awareness, and ensure the safety of themselves and others.